|

Zephyrtronics Equipment is Designed, Engineered, and Manufactured in the United States of America.

1994

The "early days" of the company as David Jacks &

Randy Walston lay ground work, engineer, R&D, test &

evaluate & apply for patents on their new, milestone

low temp approach to benchtop soldering & rework.

1995

The Company introduces world’s first stand-alone,

bottom-side preheating system, The AirBath™.

1996

Zephyrtronics awarded the "Vision Award" for Best

New Product of the Year at the San Jose Convention

Center in Silicon Valley. Motorola certifies

the Zephyrtronics equipment and methodology after

extensive laboratory testing and evaluation for the

Famous Iridium Project. Hughes

Aerospace orders 100 AirBaths™ for

its high end production facilities.

1997

SMT Magazine's editorial staff calls Zephyrtronics

one of the three most innovative companies that

year. Boeing Purchases Hundreds of Zephyrtronics AirBaths for the

Int'l Space Station Project (ISS).

1998

U.S. Department of Defense selects Zephyrtronics as

approved supplier.

Boeing tests & approves Zephyrtronics AirBath™

& LowMelt® DeSolder for

SMD removal.

Zephyrtronics aggressively litigates against a

competitor for patent infringement and is

successful. Competitor settles out of court.

1999

National Semiconductor recommends Zephyrtronics

in published paper

for

BGA rework.

Zephyrtronics defends copyright infringement by

competitor who settles for unauthorized commercial

use of technical writings.

2000

Zephyrtronics continues

3-year string as fastest growing soldering

equipment manufacturer on earth. Also:

Introduction of

dispensing product

line.

2001

In Six Sigma Study, Major Aerospace Company Reports Changing to

Zephyrtronics Would Prevent Up to $1 Million Rework Scrap

Per Year Compared To Using A Competitor's

Products.

2002

Our ZT-7-MIL is selected by The JPL Mars Rover

Project for BGA tasks.

2003

International Rectifier recommends

Zephyrtronics

for BGA rework.

2004

After smashing success of the Mars Rovers, NASA

issues 39-page touting Zephyrtronics for making

"mounting & removal of thru-hole and SMT/BGA easier

than routine bench methods"

2005

Zephyrtronics expands its leadership in preheating

with our

MegaGrid™

AirBath.

2006

Introduction of ZeroLead® branded lead-free solder paste and ZeroLead® LowMelt® DeSolder Wire.

both

are RoHS Compliant.

2007

Zephyrtronics launches

e-commerce site for the

convenience of

our global customers.

2008

Zephyrtronics Expands Its International Distribution

With New Partners & Agents in Europe, Asia, Africa,

South America, Australia and Middle East.

2009

Zephyrtronics Again Successfully Defends A Patent

Against Infringement By An Unimaginative & Cheesy

Competitor. And the Patented ZT-7

is Still the #1 BGA & SMD Hot Air Station

on Earth

2010

In the midst of global recession, Zephyrtronics

increases, yet again, its manufacturing operations,

capacity and expands its factory space by over 50%

in Los Angeles, thereby keeping its "Made in the

USA" commitment for all Zephyrtronics equipment.

2011

Zephyrtronics introduces its new highly active

pre-fluxed solder wick and a fluxless solder wick

for PCB de-soldering tasks.

2012

Company Expands Its

Multi-Function & Popular

ABC PCB Cradle Line

2013

Our Patented ZT-6 AirFountain° Approved for Space

Application Connector Soldering Because of

Superiority

Solder Joints Over

Press Fit Connectors

2014

Zephyrtronics, Yet Again, Successfully Legally

Swats the Hell Out of a Violator of One of Its May

Established Trademarks

2015

David Jacks Returns to the Helm of Zephyrtronics

Full Time. Randy Walston Establishes Even Stricter

Quality Standards than Ever Before (Which Were

Already Legendary)

2016-2017

Zephyrtronics Dependable, Original Equipment Tapped

by U.S. Military for Anti-Terrorism Fight Worldwide

Zephyrtronics Original Equipment Also Tapped by

Federal, State & Local Law Enforcement for Critical

Crime Solving Electronic Forensics.

|

|

BEHIND THE SCIENCE™ OF ZEPHYRTRONICS

The Small Engineering Company That Changed the Printed Circuit Board Assembly Workbench Forever!

|

|

|

|

|

|

|

The Zephyrtronics Company Profile:

Zephyrtronics is an engineering wholly-owned company the flagship brand of

Jacks' Technologies & Industries Corporation in

Southern California. Zephyrtronics

designs, engineers and globally markets

its technology leading concepts and products targeted primarily for the electronic

benchtop |

|

|

|

|

|

|

|

|

|

|

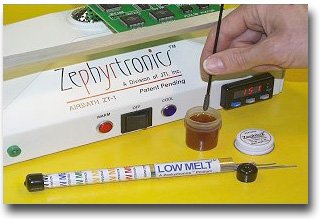

A Synergistic Approach: Preheat &

Low Temp Soldering Equipment, PCB Fixtures, Specialty & Custom

Soldering Accessories

Branded, and

Marketed by Zephyrtronics. |

|

|

|

In the early 1990's,

Zephyrtronics catapulted to its leadership role in benchtop

soldering with rapid-fire introduction of

its innovative, award-winning and patented products. Zephyrtronics,

for the first time, blended the disparate disciplines of

electronics, metallurgy, thermodynamics, and chemistry with an

uncanny ease -- delighting its expanding customer base.

Twenty years later,

those paradigm-shifting PCB processes first introduced by Zephyrtronics

have long become "industry standards" from Bangor, Maine to

Beijing, China. |

|

|

Zephyrtronics AirBath™ Invention Awarded

'Best New Product'.

1996 Surface Mount Int'l Expo

at San Jose Convention Center Silicon Valley, California |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A source of

great pride for the company is that our original equipment and products have played key

roles in the production of the International Space Station and the

three highly successful Mars Rovers and have been touted by NASA.

Over the years, both NASA and the Department of Defense have required their

sub-contractors to purchase Zephyrtronics equipment before awarding

them contracts.

From scientists at

atomic accelerators to engineers and technicians in aerospace, the

Zephyrtronics brand is top drawer. What a

Customer Base! Today, Zephyrtronics products are shipped

daily to our customers all over the world from our state of

the art factory

in Los Angeles, California. |

|

|

|

|

Cross-Industry

Applications: From such academic notables as Harvard

and Stanford Universities to the prestigious national laboratories

of JPL, NASA, Fermi, Sandia and Lawrence-Livermore; from leaders in the

semiconductor industry as Xilinx, Intel, and National

Semiconductor to the world class aerospace facilities of Hughes,

Raytheon,

Northrop-Grumman, Lockheed-Martin and Boeing; from such commercial giants as

Sony, Xerox, Hewlett-Packard, Panasonic and Phillips to even the U.S. Armed

Forces...the science of Zephyrtronics became status quo at

electronic benches transcending a dream

of two mission-driven Californian engineers into an American success

story. And transforming how printed circuit board assemblies are

designed and made. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

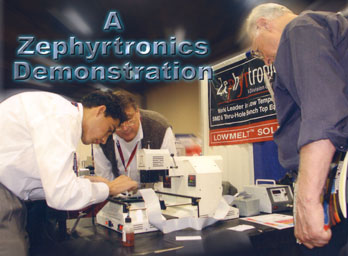

Zephyrtronics

at Trade Exposition.

More Than 1,500 Written Inquiries at

a Single Show.

|

|

|

|

|

|

|

| |

|

|

A Radical Concept! Identifying fundamental

errors in the

approach to benchtop soldering processes by older equipment

makers, the two founders of Zephyrtronics, David Jacks

and Randy Walston, developed the world's first truly

comprehensive approach to PCB benchtops.

Jacks took to the road, traveling around the

globe with a slide show pointing to a troublesome double

standard of how PCB's were made with painstaking quality in high

volume production versus how PCB's were processed, soldered or

reworked on benches. And he single-handedly introduced thermal

profiling to the electronic bench -- a concept first met with

resistance.

With chip miniaturization, multi-layer

substrates and flexible circuits, the traditional high

temp soldering tool methodology caused serious

quality, reliability (costly) problems. |

|

|

Benchtop

Synergy! Developing and packaging

new equipment, and accessories that all complimentary to each other,

Zephyrtronics crossed

over and into traditionally defined "markets" to directly

reach out to electronic technicians. And that "cross over" stirred

up quite a hornet's nest!

Word of mouth

between engineers and technicians of this new benchtop "science"

spread quickly and demand exceeded the company's initial production

capacity. Brand loyalty to Zephyrtronics was something to

behold.

Zephyrtronics consistently

drew the largest crowds at normally staid electronic expositions.

Manufacturing and quality engineers -- hardly folks given to

euphoria -- were tossing their business cards through

the mobs requesting Zephyrtronics

to visit their facilities. |

|

|

|

|

|

|

|

|

|

|

|

|

Accolades & Industry Recognition

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

editorial staff of the electronic devices trade journal,

SMT Magazine witnessed the fever Zephyrtronics products were

causing and singled out the young company as one of the "three

most innovative" in 1997 declaring Zephyrtronics

produced a "simpler, safer way to remove and repair

sensitive devices." First at the

Benchtop: Whether it was PCB thermal profiling,

ramping, preheating, post-cooling™, patented single-spot BGA

alignment and reflow, successful use of solder paste at the bench,

or non-contact

desoldering, Zephyrtronics was first at the bench to do

so. |

|

|

|

So Far Ahead of

the Curve: Two decades later, every significant

soldering equipment manufacturer on earth has been

influenced by and (if possible without patent infringement) have

acknowledged they incorporated

Zephyrtronics' original concepts into their own

products. Of course, this forced them to obsolete entire

product lines they had marketed for years to "keep up" with Zephyrtronics.

And so it is still today where students of

physics and electronics in university labs are employing the

equipment, alloys, processes and PCB techniques pioneered by

Zephyrtronics. |

|

|

|

|

|

|

"Innovative...simpler, safer way to remove and repair sensitive devices"

-- Editorial Staff

SMT MAGAZINE |

|

|

|

Zephyrtronics Wins

'Best New Product' at 1996 Surface Mount Int'l Expo in Silicon Valley |

|

|

Zephyrtronics AirBath™

is Featured in

Ray Prasad's 1997 Definitive Text

Surface Mount Technology |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

TM

Zephyrtronics

Signature

Design.

The Patented ZT-2 AirPencil™

at Home in the Smithsonian |

|

|

Our Customers Matter Most.

When it comes to our customers, Zephyrtronics is old fashioned,

which means they matter. Zephyrtronics equipment has the longest

warranties in our industry.

We still have original customers from twenty years ago

with us and we hear over and again how their

original Zephyrtronics equipment is still working after all these

years. Very few, if any, within the soldering industry can say that

today. That customer loyalty is at the very foundation of our

company. |

|

TM

Zephyrtronics

ZT-5100 Automatic Dispenser |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Looking Back Twenty Years Later...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

"I have to laugh at it all now because, in

hindsight, I can tell you that we never gave it a second thought,"

commented Jacks, president of Zephyrtronics. "Fortunately, we were just naive

and foolhardy enough way back then to believe that technicians and

engineers would respond favorably if we gave them better

tools and solutions. And they did far more

than we ever imagined. I never dreamed one day I'd have the honor to stand on

the USS Kitty Hawk flight deck knowing Zephyrtronics gear was used

below." |

|

|

|

The USS Kitty Hawk

Aircraft Carrier |

|

|

|

Jacks continues, "Our

opportunity was that key manufacturers of benchtop soldering

equipment were just so satisfied, set in their ways, resisting change

and unaware of emerging technologies. Complacency gave us an opening to change

things in a big way.

"The old giant soldering companies

had no clue how irrelevant their products had

become to current chip

technologies and how their approach to the bench was simply Jurassic...and

then they began copying us." |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

Zephyrtronics ZT-7 System

Is Now a Standard at Electronic Benchtops Around the World |

|

|

|

|

|

|

|

Recognizing

the reality that the benchtop market, like others, is not only highly

competitive, but also imitative, Jacks and Walston remain nonplussed.

Walston wryly adds, "I guess I should feel somewhat guilty knowing

we inspired so many lousy imitations and how

they can confuse the market a bit, and worse, frustrate

poor technicians who get stuck using them." |

|

Still, engineers and techs continue to specifically seek out the Zephyrtronics

brand as they have in the past. Indeed, some of the most

prestigious names in the electronic manufacturing industry

schedule their budgets around upcoming products

that Zephyrtronics has only shown at trade shows and yet to

release. Jacks grins, "naturally, all of this drives our

competition absolutely nuts with envy." |

|

|

|

|

| |

The Zephyrtronics ZT-7 Chosen By NASA & JPL

for the

Successful Mars Rover Program. NASA Issued 39-Page

Report Touting the System. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

With detailed milestone charts for a

host of future new product introductions, Zephyrtronics

still remains dedicated to the same principles that

fueled the company's impressive and rapid growth from

the early days: simplicity through innovation, fanatical

commitment to quality and premium products at affordable

prices. |

|

|

|

And

adds Jacks, "we give the highest

respect possible for our customers. Even after all these

years of success, we are mindful that we are still just

that little soldering and preheating company from Los

Angeles. But did I tell you we forever changed and

improved the

way PC boards are made in labs and production facilities

around the planet?" |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

©1996 - 2011, 2012, 2013, 2014, 2015, 2016, 2017-2018, 2019,

2020 - 2023 by Zephyrtronics®. All rights reserved.

The information, text, images, photographs, charts, graphs you

receive online from Zephyrtronics® are protected by the

copyright laws of the United States. The copyright laws prohibit

any copying, redistributing, retransmitting, or repurposing of

any copyright-protected material. Zephyrtronics is the

registered trademark property of JTI, Inc. "The Science of

Zephyrtronics" and "Simplicity Through Innovation" and "Zephlux"

and "ZeroLead" and "Zero Balling" and "Zero Residue" and "Post

Cooling" and "Post Cooler" and "AirBath" and "SolderGlide" and

"ZeroTouch" and "SolderMill" and "Just So Superior" are the protected trademark

property of JTI, Inc. "Zephyrtronics" and "Low Melt" and "Air

Fountain" and "Fountainhead" are the registered trademark

properties of JTI Inc. *The above names are the registered

property of their respective owners. |

|

|

|

|

|

|

|

Product Directory

Contact Us

About Us

Privacy & Website Statement

Terms & Conditions, Conditions of Use, Warranties, Liability,

Intellectual Property, Trademarks, Patents, Copyrights & Use

of Website Statement

SMD

Rework,

SMT Rework

AirBath Air Bath,

SMD Rework Stations,

Hot Air Pencil Soldering,

BGA Rework Stations,

CSP Rework Stations,

Preheating Systems,

PCB Preheaters,

Pre-Heat SMT/ SMD,

Low Temp Rework,

SMT DeSoldering Tools,

Vacuum Pickup Tools,

Circuit Board Holders,

PCB Fixture & PCB Holders

&,

Board Cradles,

Rework Solder Paste,

No-Clean Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder Wire,

Hot Air Rework Stations,

Fume Extractors,

SMT Dental Probes,

SMT, SMD Rework Kit,

BGA Rework Kit,

LMK Kit,

BGA Re-Balling Kit,

SMD Tweezers,

Power Palm Plunger,

QFP Lead Straightener

Soldering,

De-Soldering

Soldering Accessories,

Solder Wire,

No-Clean Solder Wire,

Eutectic Solder Wire,

Solder Wire Dispenser,

Solder Paste,

Lead-Free Solder Paste,

Flux,

Solder Paste Dispensers,

Low Melt®

DeSolder Wire,

De-Solder Wire,

Soldering Tips,

Thru-Hole DeSoldering

Tools,

DeSoldering Tips,

Tips for DeSoldering,

De-Solder Wick &

DeSoldering Braid,

Smoke Extractors,

Fume Extractor Filters,

Carbon Activated Filters,

SolderMill™,

Solder Sucker / DeSolder

Pump,

Pre-heating Systems,

Preheat Thru-Hole,

PCB Pre-heaters,

Flux Solvent,

How To - Connector Rework;

How To - PC/104 Soldering

and Rework;

How To - Thru-Hole /

Through Hole Desolder / De-Solder;

How To - Low Melt®

Desolder Wire;

How To- Stop Lifting Pads;

How To- Desolder /

De-Solder Heavy Ground Planes;

How To - Lead-Free

Soldering and De-Soldering;

Pre-Heaters for Lead-Free Rework and Soldering

Dispensing Equipment, Gear, Supplies, Dispensing

Bottles & Dispensing Accessories

Dispensing Systems,

Dispensing Syringes,

Dispensing Barrels,

Tapered Dispensing Tips,

Blunt Needles,

Dispensing Bottles,

Stainless Steel Needles,

Dispensing Needles,

Industrial Needles,

Dispensing Tips,

Industrial Dispensing

Tapered Tips and Needles,

Dispensing Accessories,

Flux Bottles,

Solder Paste in Syringe,

Paste Rack Solder Paste

Holder™,

Dispensing Supplies,

Power Palm Plunger,

Manual Dispensing,

Alcohol Pump Bottles,

Automatic Dispensing,

Squeeze Bottles, Wash

Bottles, Brush Bottles, Spout Bottles, Pump

Bottles |

|

|