|

|

|

|

|

|

Ball Grid Array Reballing How to ReBall BGA's

ReBalling Stencils BGA Spheres & Solder

Balls. Helpful Tips. |

|

|

|

BGA

RE-BALLING QUALITY METHOD

This is the Original

"Zephyrtronics Way" of Re-Balling Used Globally. |

|

|

|

|

|

|

|

|

|

|

|

| |

|

HOW TO: |

|

Reballing Ball Grid Arrays is easy, but

quality is paramount. Here are ten simples

steps! Note: We interchange the words

"stencil" and "screen" here as they are both

used in the industry. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

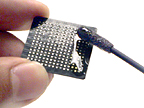

1. Apply a thin film of a

very tack, no clean flux (Zephlux™

(NCF-0014

) over entire grid area of the BGA package using an

anti-static foam swab

as shown at left. Our tack flux "holds" your chip in position

with the stencil (next step). |

|

|

|

|

|

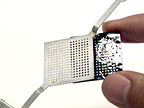

2. Match the

appropriate re-balling screen for your BGA pattern. Place your

component (with the tack flux applied as shown above) onto

the underside of your reballing screen/stencil. Make sure your

component and the stencil are squared. Do NOT use liquid (runny)

fluxes or paste fluxes (stringy).

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

Ideally, position a "Re-Balling Pan"

under the Stencil. Place chip into

Re-Balling Pan so that the handles of

stencil lay directly above those of the

Re-Balling Pan as shown at left. Note how

well the "tack" flux holds chip and stencil

together! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Pour appropriate Solder Spheres onto

Re-Balling Screen. Securing both handles of

the stencil, rotate left & right dumping any

excess spheres into the Tank. If your

stencils don't have handles, you can secure

the stencil with your Kapton®

tape or other ways easily enough. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.

Next up: the

ZT-3 Air Pick™

with a Re-Balling Needle Tip (from our

popular

ZT-5-VPAK variety tip pack) to hold your

Solder Spheres onto the end of the AirPick™.

The AirPick™

features the unique "quick vacuum release"

critical when trying to get the job done. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.

Now, use your ZT-3-AirPick™

to remove any extra, loose and "rolling

around" Solder Spheres from out of the

stencil. Also use your AirPick to fill in

any holes on your Re-Balling Screen as shown

here. The Zephyrtronics way of using a tank

is helpful as it catches all the extra

solder spheres. |

|

|

|

|

|

|

|

|

|

|

|

|

A Good BGA Re-Balling Set-Up or Station Should Include All of

the Following:

• Solder Spheres for Re-Balling

Vial of 10K -30

Mil Diameter

Vial of 10K -25 Mil Diameter

Vial of 10K -20 Mil Diameter

Vial of 10K -12 Mil

Diameter

• Re-Balling Stencil/Screen (BGA Pattern)

•

Re-Balling Pan, • Re-Balling Platform

• Re-Balling Tank (If

possible)

• Re-Balling

Needle Tip

Pack (ZT-5-VPAK)

•The

ZT-1

AirBath™ Bottom-side Preheat

•

LowMelt® DeSolder

Wire 487

•

AirPick™

Vacuum Lifting System

• Zephlux™

Tacky Flux

• Non-Flammable

Flux Remover

• Scrub

Brushes

•

Foam Swabs,

ESD Safe

&

Solder Wick

• Set of Two Stainless Steel

Tweezers

Be Sure You Verify if You are Working With Tin/Lead or Lead-Free

Alloys.

|

|

|

|

|

| |

|

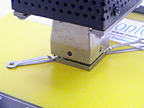

7.

Place the Re-Balling Platform (out of VO

non-flammable glass fiber board) into your

ABC-1 Board Cradle™.

Position the the Cradle in front of your

ZT-7-MIL. Now,

simply place the Re-Balling Pan and Re-Balling Screen on top

of the ReBalling Platform.

Using a

Zephyrtronics AirBath™ from below,

preheat your chip (very important) at this stage. Remember,

a BGA is essentially a very small and delicate PCB so

preheat is really needed! |

|

|

|

|

|

|

|

|

|

| |

|

|

8.

After a 1-2 minute preheat (soak) of the chip

and spheres, you can next lower the Z-axis heating zone of

the ZT-7-MIL down to where the hot air nozzle is

approximately 1/8" or 3mm above the Re-Balling unit. Set

your countdown timer to 1:20 to 1:30 for most chips. Set

your top temperature to 230ºC to 250°C for most chips. Start

the timer and the heating from above. |

|

|

|

|

|

|

|

|

| |

|

|

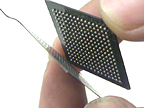

9.

Yes! The picture at the left says it all. When the timer

begins to beep, turn off top heater. As the Re-Balling unit

cools, carefully separate the component out from the screen

as shown in the photograph at the left. (Caution: The

Re-Balling unit may still be hot.) Inspect your component

and you are ready for final cleaning. |

|

|

|

|

|

|

|

|

|

| |

|

|

|

10.

Final Cleaning: Dip one of your

Scrub Brushes

into the

non-flammable

flux remover (NFR-0056, also included in the Kit!).

Generously apply the flux-remover throughout the component

until all of the old flux has been stripped away. Inspect.

Note: If you are re-using the same

BGA, but need to remove the old solder, use the ZT-1 AirBath™

together with our famous

LowMelt® DeSolder

Wire. Oh, yeah. Ideal application. |

|

|

|

|

|

|

|

|

Ten Easy to Follow Steps for

High Quality Re-Balling!

We've made it easy for you!

Don't be shy! Give us

a call or e-mail us today

at

david@zeph.com

with any

questions. We are always happy to assist

you. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

©1996 - 2011, 2012, 2013-2017, 2018, 2019, 2020 by Zephyrtronics®. All rights reserved.

The information, text, images, photographs, charts, graphs you

receive online from Zephyrtronics® are protected by the

copyright laws of the United States. The copyright laws prohibit

any copying, redistributing, retransmitting, or repurposing of

any copyright-protected material. Zephyrtronics is the

registered trademark property of JTI, Inc. "The Science of

Zephyrtronics" and "Simplicity Through Innovation" and "Zephlux"

and "ZeroLead" and "Zero Balling" and "Zero Residue" and "Post

Cooling" and "Post Cooler" and "AirBath" and "SolderGlide" and

"SolderMill" and "Just So Superior" are the protected trademark

property of JTI, Inc. "Zephyrtronics" and "Low Melt" and "Air

Fountain" and "Fountainhead" are the registered trademark

properties of JTI Inc. *The above names are the registered

property of their respective owners. |

|

|

|

|

|

|

|

|

|

|

|

Click Here to Go Directly to Our Easy-to-Navigate and

Illustrated Product Directory. |

|

|

|

|

|

|

|

|

|

|

|

|

SMD

Rework,

SMT Rework

AirBath Air Bath,

SMD Rework Stations,

Hot Air Pencil Soldering,

BGA Rework Stations,

CSP Rework Stations,

Preheating Systems,

PCB Preheaters,

Pre-Heat SMT/ SMD,

Low Temp Rework,

SMT DeSoldering Tools,

Vacuum Pickup Tools,

Circuit Board Holders,

PCB Fixture & PCB Holders

&,

Board Cradles,

Rework Solder Paste,

No-Clean Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder Wire,

Hot Air Rework Stations,

Fume Extractors,

SMT Dental Probes,

SMT, SMD Rework Kit,

BGA Rework Kit,

LMK Kit,

BGA Re-Balling Kit,

SMD Tweezers,

Power Palm Plunger,

QFP Lead Straightener

How

To - SMT, CSP, BGA Rework

How To - BGA Alignment;

How To - SMT Rework;

How To - PCB Preheating,

How To - BGA & CSP Rework;

How To - Quickly Solder

SMD Packages Effectively;

How To - CSP Alignment;

How To - Lead-Free Rework;

How To - SMD Removal

Economical;

How To - SMD Removal

Professional;

How To - Hot Air Pencil /

AirPencil Soldering;

How To - SMD Quick Chip

Removal;

How To - BGA Re-Balling;

How To - Rework PLCC, QFP,

QFN, LCC, SOIC, SOL, Shielded SMD, TSOP;

How To - Solder & Rework

Ceramic Capacitors;

How To - Solder & Rework

Glass Diodes;

How to Repair Smartphones,

Tablets and Laptops

Soldering,

De-Soldering

Soldering Accessories,

Solder Wire,

No-Clean Solder Wire,

Eutectic Solder Wire,

Solder Wire Dispenser,

Solder Paste,

Lead-Free Solder Paste,

Flux,

Solder Paste Dispensers,

Low Melt®

DeSolder Wire,

De-Solder Wire,

Soldering Tips,

Thru-Hole DeSoldering

Tools,

DeSoldering Tips,

Tips for DeSoldering,

De-Solder Wick &

DeSoldering Braid,

Smoke Extractors,

Fume Extractor Filters,

Carbon Activated Filters,

SolderMill™,

Solder Sucker / DeSolder

Pump,

Pre-heating Systems,

Preheat Thru-Hole,

PCB Pre-heaters,

Flux Solvent,

How To - Connector Rework;

How To - PC/104 Soldering

and Rework;

How To - Thru-Hole /

Through Hole Desolder / De-Solder;

How To - Low Melt®

Desolder Wire;

How To- Stop Lifting Pads;

How To- Desolder /

De-Solder Heavy Ground Planes;

How To - Lead-Free

Soldering and De-Soldering;

Pre-Heaters for Lead-Free Rework and Soldering

Dispensing Equipment, Gear, Supplies, Dispensing

Bottles & Dispensing Accessories

Dispensing Systems,

Dispensing Syringes,

Dispensing Barrels,

Tapered Dispensing Tips,

Blunt Needles,

Dispensing Bottles,

Stainless Steel Needles,

Dispensing Needles,

Industrial Needles,

Dispensing Tips,

Industrial Dispensing

Tapered Tips and Needles,

Dispensing Accessories,

Flux Bottles,

Solder Paste in Syringe,

Paste Rack Solder Paste

Holder™,

Dispensing Supplies,

Power Palm Plunger,

Manual Dispensing,

Alcohol Pump Bottles,

Automatic Dispensing,

Squeeze Bottles, Wash

Bottles, Brush Bottles, Spout Bottles, Pump

Bottles

Benchtop Accessories,

Bench Supplies,

Benchtop Tools

SMD Solder Paste,

Solder Wire,

LowMelt®,

No-Clean Flux,

BGA Flux,

Rework Tack Flux,

Non-Flammable Flux Remover,

Pen Vac,

SMT Tweezers,

Fume Extraction,

SMD Tweezers,

PC Board Fixtures,

Hot Air Tips,

AirTips,

Replacement Soldering

Sponges,

Iron Plated Soldering Tips,

Foam Swabs,

Anti-Static Foam Swabs,

Thru-Hole & Solvent

Brushes,

Helping Hands,

LMK Rework Kits,

X-BOX 360 Repair,

Wire Strippers & Wire

Cutters,

Flush Cutters, Micro

Shears & Needle Nose Piers,

Straightening Tool for

QFP Leads,

ESD Wrist Straps,

ESD Wrist Strap Tester

Updated

for April 22, 2020 |

|

|

|

|