|

|

|

|

|

|

|

How To Solder SMT Components & Chips How to Use Solder Paste With Your PCB's SMD Soldering

|

|

|

|

SMD SOLDERING AS IT SHOULD BE!

We Pioneered Using Solder Paste First at the Benchtop Instead of Solder Wire. Nearly 30 Year Ago!

|

|

| |

Here’s Just How Simple High-Quality SMD Soldering Can Be With Shiny Solder Joints & Fillets!

|

|

|

|

|

|

|

|

|

|

|

Apply Bead of Solder Paste.

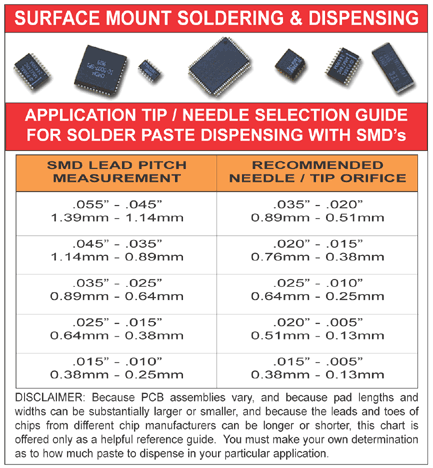

With the appropriate gage of

paste application tip (See

Selection Chart Below),

apply a continuous bead of

solder paste down the middle

of the pads (Recommended:

Zephpaste SPE-0012) as

shown here. |

|

|

|

|

|

|

|

|

|

|

Pick and Place Chip. Using an

ESD safe, and soft vacuum lifting device

such as the

ZT-3-MIL AIRPICK, lift and gently

place the selected SMD on top of the

bead of paste above the corresponding

pads. |

|

Adjust Alignment if Needed. After

placing SMD, check so all leads and pads are

aligned. "Fine tune" with a stainless steel

SMD or Dental Probe as shown. Recommended (SMT

Probes SDP-1111). |

|

|

|

Always Preheat. Switch the

ZT-1 AIRBATH to "Warm" at

industry

recommended setting of 150°C. How long?

The process itself will tell you. When

bead of solder paste runs (30-60 sec),

flux has activated and the PCB is

preheated. |

|

|

|

Using a Low Velocity Hot Air

Pencil with precision,

pin-pointed AirPencil, apply

heated airstream to shoulders of

the SMD's leads (not the pads).

Allow time so that all solder

wicks up making shiny joints

with fillets one joint at a

time. Inspect.

Recommended:

ZT-2-MIL AirPencil.) |

|

|

|

Cool Down & Final Cleaning.

Flip rocker switch of

ZT-1 AirBath

to "Cool" mode to cool down PCB. Dip a large anti-static foam

swab into non-flammable flux solvent or remover.

We recommend

Non-Flammable Flux Remover |

|

|

|

|

Swab PCB with Flux Remover.

As PCB cools under

ZT-1 AirBath, swab area

where SMD was placed and

reflowed to the pads with Flux

Remover as shown. Turn off

AirBath. Inspect. (For graphic

contrast, a white foam swab is

shown at left.). |

|

|

|

|

|

|

|

|

|

|

|

|

Inferior Soldering Iron with Solder Wire

Vs

Superior Hot

Air Soldering & Solder Paste

|

|

|

|

Above: An inferior "tack" solder joint made with the traditional,

contact soldering iron and solder wire. At best, only a tangential joint is achieved at the lead/pad interface. Such inferior joints are no more acceptable from the bench than they

are from a conveyor oven or wave solder machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Above: A superior solder joint for SMD's.

Here's how to make good solder joints: A bead of solder paste is applied to the pads, followed by placement of the SMD onto the pad and seated into the paste.

Next, a brief preheating of the bottom side of the PCB is made. After 30-60 seconds, flux activation begins (solder bead begins to visibly level).

A localized, pin-pointed reflow of solder paste is made at each individual lead/pad interface with a low velocity hot air pencil. Solder wets and wicks up to the lead's toes, heels and sides with production quality fillets.

It's elementary:

What is a good solder joint? A solder joint made at the bench with the same materials and processes used in premium production conveyor ovens will be the same.

This only requires the following:

a) solder paste (not wire)

b) convective preheating prior to

reflow

c) convective reflow (hot air pencil)

not messy contact (soldering iron)

For a more in depth look at SMD soldering, please refer to

"Making High Quality Solder Joints at the Bench". |

|

|

|

|

Zephyrtronics

Popular

No Clean

Solder Paste

6 Month Shelf

No Refrigeration

Available in

Un-Leaded & Leaded Alloys!

Click Photo |

|

|

|

|

|

|

|

| |

|

A Few Extra Notes:

The above example is made with a "gull winged " SOIC

20. This same method works equally well with the "J"

leaded PLCC's. For finer pitched components, such as

the popular QFP 100 and the QFP 208, a slight

variation in technique is easily made with equally,

if not even more effective results (call

Zephyrtronics for details...we can't teach our

competitors all of our tricks).

For SMD

Component Removal, please be sure to see LowMelt®

Process of Co-Metalization and Rapid SMD Removal in

Less Than 180 Seconds and learn more about the

history and benefits of the popular Zephyrtronics

LowMelt DeSolder®.

Please note: Zephyrtronics has conveniently packaged

all of the above described chemicals, ZephPaste

Solder Paste, Anti-Static Swabs, SMT/Dental Probes,

LowMelt®

DeSolder and more in the

LMK-1000 SMD Benchtop Kit our Blueprint for the

Bench™, or best of all, please visit our

Systems Section in this Website where our more

popular, comprehensive benchtop systems are

graphically presented. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

©1996 - 2011, 2012,

"SolderGlide" and "SolderMill"

and "ZeroTouch" and "Just So Superior" are the protected trademark

property of JTI, Inc. "Zephyrtronics" and "Low Melt" and "Air

Fountain" and "Fountainhead" are the registered trademark

properties of JTI Inc. *The above names are the registered

property of their respective owners. |

|

|

|

|

|

|

|

|

| |

|

| |

|

|

SMD

Rework,

SMT Rework

AirBath Air Bath,

SMD Rework Stations,

Hot Air Pencil Soldering,

BGA Rework Stations,

CSP Rework Stations,

Preheating Systems,

PCB Preheaters,

Pre-Heat SMT/ SMD,

Low Temp Rework,

SMT DeSoldering Tools,

Vacuum Pickup Tools,

Circuit Board Holders,

PCB Fixture & PCB Holders

&,

Board Cradles,

Rework Solder Paste,

No-Clean Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder Wire,

Hot Air Rework Stations,

Fume Extractors,

SMT Dental Probes,

SMT, SMD Rework Kit,

BGA Rework Kit,

LMK Kit,

BGA Re-Balling Kit,

SMD Tweezers,

Power Palm Plunger,

QFP Lead Straightener

How

To - SMT, CSP, BGA Rework

How To - BGA Alignment;

How To - SMT Rework;

How To - PCB Preheating,

How To - BGA & CSP Rework;

How To - Quickly Solder

SMD Packages Effectively;

How To - CSP Alignment;

How To - Lead-Free Rework;

How To - SMD Removal

Economical;

How To - SMD Removal

Professional;

How To - Hot Air Pencil /

AirPencil Soldering;

How To - SMD Quick Chip

Removal;

How To - BGA Re-Balling;

How To - Rework PLCC, QFP,

QFN, LCC, SOIC, SOL, Shielded SMD, TSOP;

How To - Solder & Rework

Ceramic Capacitors;

How To - Solder & Rework

Glass Diodes;

How to Repair Smartphones,

Tablets and Laptops

Soldering,

De-Soldering

Soldering Accessories,

Solder Wire,

No-Clean Solder Wire,

Eutectic Solder Wire,

Solder Wire Dispenser,

Solder Paste,

Lead-Free Solder Paste,

Flux,

Solder Paste Dispensers,

Low Melt®

DeSolder Wire,

De-Solder Wire,

Soldering Tips,

Thru-Hole DeSoldering

Tools,

DeSoldering Tips,

Tips for DeSoldering,

De-Solder Wick &

DeSoldering Braid,

Smoke Extractors,

Fume Extractor Filters,

Carbon Activated Filters,

SolderMill™,

Solder Sucker / DeSolder

Pump,

Pre-heating Systems,

Preheat Thru-Hole,

PCB Pre-heaters,

Flux Solvent,

How To - Connector Rework;

How To - PC/104 Soldering

and Rework;

How To - Thru-Hole /

Through Hole Desolder / De-Solder;

How To - Low Melt®

Desolder Wire;

How To- Stop Lifting Pads;

How To- Desolder /

De-Solder Heavy Ground Planes;

How To - Lead-Free

Soldering and De-Soldering;

Pre-Heaters for Lead-Free Rework and Soldering

Dispensing Equipment, Gear, Supplies, Dispensing

Bottles & Dispensing Accessories

Dispensing Systems,

Dispensing Syringes,

Dispensing Barrels,

Tapered Dispensing Tips,

Blunt Needles,

Dispensing Bottles,

Stainless Steel Needles,

Dispensing Needles,

Industrial Needles,

Dispensing Tips,

Industrial Dispensing

Tapered Tips and Needles,

Dispensing Accessories,

Flux Bottles,

Solder Paste in Syringe,

Paste Rack Solder Paste

Holder™,

Dispensing Supplies,

Power Palm Plunger,

Manual Dispensing,

Alcohol Pump Bottles,

Automatic Dispensing,

Squeeze Bottles, Wash

Bottles, Brush Bottles, Spout Bottles, Pump

Bottles

Benchtop Accessories,

Bench Supplies,

Benchtop Tools

SMD Solder Paste,

Solder Wire,

LowMelt®,

No-Clean Flux,

BGA Flux,

Rework Tack Flux,

Non-Flammable Flux Remover,

Pen Vac,

SMT Tweezers,

Fume Extraction,

SMD Tweezers,

PC Board Fixtures,

Hot Air Tips,

AirTips,

Replacement Soldering

Sponges,

Iron Plated Soldering Tips,

Foam Swabs,

Anti-Static Foam Swabs,

Thru-Hole & Solvent

Brushes,

Helping Hands,

LMK Rework Kits,

X-BOX 360 Repair,

Wire Strippers & Wire

Cutters,

Flush Cutters, Micro

Shears & Needle Nose Piers,

Straightening Tool for

QFP Leads,

ESD Wrist Straps,

ESD Wrist Strap Tester

Updated

|

|

|